Précision.

Flexibilité.

Agilité.

Flexibilité.

Agilité.

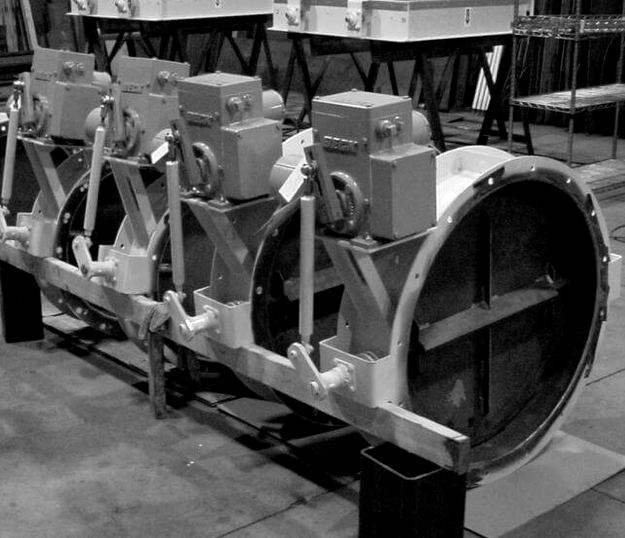

Maître dans la découpe et l’assemblage de pièces mécano-soudées

DÉCOUPE

Chaque découpe nous permet de réaliser avec précision et netteté les projets de nos clients. Ce procédé n’endommage pas les matériaux, pour un produit final de qualité supérieure.

Notre expertise à l’écoute de vos besoins

Une coupe nette et précise de tous les matériaux.

Une découpe des matériaux plus épais et une plus grande précision de coupe.

Le laser, rien ne lui résiste.

Notre équipe se démarque par son expertise en mécano-soudure. Obtenez un accompagnement personnalisé pour un projet clés en main, selon vos plans et devis.

DÉCOUVREZ-EN PLUS SUR NOS EXPERTISES

Une clientèle

satisfaite

Notre équipe se démarque par son expertise en recherche mécano-soudée. Obtenez un accompagnement personnalisé pour un projet clés en main, selon vos plans et devis.